Products

Cutting Tools

category

- WIN-SWISS (QE1)

- WIN-I-GROOVE (TMIR/L)

- WIN-I-GROOVE (TMIR/L)

- WIN-4-FEED (BLMV)

- XM-REAM (XR)

- WIN-MILL (AVK(C)T)

- QUAD-RUSH_Swiss Machines

- BT FC

- WIN-DRILL (TCD)

- WIN-DRILL (TCD-MRS,TCDM)

- CHASE-8-SFEED (SQKU)

- MAXI-TANG (LXHU)

- CHASE-8-SFEED (SQKU)

- CERAMIC-SFEED (BNGX)

- MODU-R-DRILL (MDB)

- SOLID-3-DRILL (3HD)

- CHASE-4-FEED (BLMP)

- CHASE-2-FEED (BLMP 13)

- CHASE-10-MILL (PTKU)

- NAN-RUSH (HFN)

- WIN-MILL (CVKT)

- TANG-SFEED (LPKU)

- CHASE-8-MILL (SQKU)

- CHASE-4-MILL (4NKT, 4NHT)

- CHASE-V-QUAD (SVKT)

- CHASE-12-MILL (HXKU, HXHU)

- CHASE-4-FINISH (4WHU)

- CHASE-10-MILL (PTKU)

- MAXI-SFEED (TR-)

- MAXI-RUSH (MX..)

- SLIK-SOLID (UHP 4)

- 5-Axis Profiling (SCS…,MXCS…)

- CERAMIC-SFEED (CR.)

- SFEED-BARREL (BRHU)

- FINE-BARREL (NFLB, NFCB)

- Carbide Endmills (SCS…,MXCS…)

- CHASE-SPEED for super alloys

- WIN-SWISS (QE1)

- MULTI-L-TURN (VBMX)

- Chip Breakers for Steel (..P)

- RHINO-TURN Series

- T-CLAMP for Swiss Machines

- TOP-CUT for Swiss Machines

- MINI-I-RUSH for Swiss Machines

- J & C Type Chip Breaker

- TDV & TDUF Inserts

- TDXU & TDXY Inserts

- T Type Chip Breaker

- TDT-RU Chip Breaker

- TDIM & TDIP Inserts

- Aluminum Wheel Machining Inserts

- Tailor Made Inserts

- TOP-MINI Positive Inserts

- TOP-MINI Holders

- TT7505 Grade

- QUAD-RUSH (TQC/J/S 27, TQC 34)

- QUAD-RUSH (TQJ/S 20)

- COOL-BURST High Pressure Coolant Holders

- TOP-MICRO for Swiss Machines

- T-THREAD (Thread Turning)

- TS-THREAD (Thread Milling)

- Modular System

- T-TAP (TPH-52B, TPH-54C)

- TOP-DRILL (TOP, SOMT)

- T-DRILL (TDR, SPMG)

- TOP-CAP (TCAP, XCMT)

- H-DRILL (NHD, NHD-K)

- M.Q.L-DRILL (SHO, Long Drill)

- T-DEEP (TRGD, Indexable Gun Drill)

- T-DEEP (BTA Drill)

- TM-REAMER (Head changeable)

- TB-REAMER (Blade type)

- T-GROOVE special solutions

- CHASE-FEED (SBMT)

- MILL-RUSH (3PKT)

- MILL-2-RUSH (6N*U, TNMX)

- CHASE-P-MILL (2PKT)

- CHASE-MILL (APKT)

- CHASE-ALU (XEVT)

- CHASE-HEPTA (7EMT)

- CHASE-2-HEPTA (XNMU, XNHU)

- CHASE-2-QUAD (SNMX, SNGX)

- CHASE-2-MOLD (RNMU)

- CHASE-MOLD (RYMX, RYHX)

- FINE-BALL (NFB/NFR)

- DUET-BALL (2FB)

- CHASE-2-BALL (6RBE)

- TRIO-BALL (3FB)

- TOP-SLOT (ZNHT, ZNHU, SLOT, TS16)

- Slotting Cutters (TIMC, TIMJ, TIPV)

- STAR-MILL (SED, SER, SBT, REH)

- HARD-MILL (HSF, HSR, HSB)

- Chamfering (HCEM)

- SOLID-FEED (HFM)

- VFI-MILL (CFM)

- MULTI-MILL (FSM)

- ALU-MILL (AES, AWE, REA, REMA)

- DIA-MILL (R*FE, RCOM, RDCF, D**)

- T-SHRINK

- T-BALANCE

- MPT

- QUAD-RUSH (TQBS)

- VT-CLAMP (TDMV)

- MILLING CHUCK (-NTMC)

- CUT-SFEED

- DRILL-SFEED (3ED)

- External Turning Tool Holders

- POS-S-TURN (XNMV)

- TURN-SFEED (FCMX)

- POS-S-TURN (ZNMV)

- RHINO-X-TURN (XNMG)

- RHINO-M-TURN (C/W/DNMX)

- HUSH-BORE (QH/QS)

- COOL-BURST (T…-TB)

- CUT-SFEED (SFC/J)

- QUAD-RUSH (TQS/J 20)

- QUAD-I-RUSH (TQIS)

- MINI-I-RUSH (TMIS)

- FACE-RUSH (TDFX)

- TSG-HF CBN Inserts

- SOLID-3-DRILL (3HD)

- DRILL-SFEED (3ED)

- DRILL-RUSH (TCD)

- MODU-R-DRILL (MDB)

- TANG-SFEED (LPKU)

- CHASE-4-MILL (4NKT)

- CHASE-8-MILL (SQKU)

- CHASE-4-FEED (BLMP)

- WIN-TURN (TNMV)

- MULTI-L-TURN (VBMX)

- HUSH-MODU (QSS, C…CS)

- WIN-TURN (TNMV)

- POS-S-TURN (XNMV)

- CHASE-2-MILL (ANHX, ANMX)

- TS-REAMER (Solid carbide)

- Inserts for Super Alloys

- SFEED-RUSH (CVD coated)

- Ceramic Inserts

- CBN and PCD Inserts

- DRILL-RUSH (TCD)

- SPADE-RUSH (LCD)

- BT FC

- SFEED-TEC Overview

- Holemaking by Products

- TURN-SFEED (FCMX)

- Milling by Applications

- POS-S-TURN (ZNMV)

- Thread Making by Products

- Tooling System by Products

- CDF-DRILL for CFRP (CDF)

- RHINO-X-TURN (XNMG)

- Turning Overview

- RHINO-M-TURN (C/W/DNMX)

- MINI-I-RUSH_Internal Shallow Grooving(TMIS)

- COOL-BURST (T…-TB)

- QUAD-I-RUSH_Internal Shallow Grooving(TQIS)

- WIN-CUT & CUT-SFEED (SFC/J)

- FACE-RUSH (TDFX)

- Parting & Grooving Overview

- Internal Turning Tool Holders

- HUSH-BORE (QH/QS)

- HUSH-MODU (C…CS)

- RHINO-M-TURN (C/W/DNMX)

- COOL-BURST High Pressure

- Heavy Duty Machining

- Chip Splitter Type Inserts (-SM, -SAL)

- CHASE-12-MILL (HXKU, HXHU)

- CHASE-10-MILL (PTKU)

- CHASE-4-FINISH (4WHU)

- CHASE-V-QUAD (SVKT)

- NAN-RUSH (HFN)

- MILL-RUSH (3PKT)

- MAXI-RUSH (MX..)

- MAXI-SFEED (TR-)

- CERAMIC-SFEED (BNGX)

- CERAMIC-SFEED (CR.)

- The others

-

RHINO-M-TURN

(Mini Size Negative Inserts) - TSK SLIM CHUCK (-TSK )

-

RHINO-TURN-SWISS

(Eco Type Negative Inserts) - Grade Selection Guide

- T-CLAMP_Parting & Deep Grooving

- QUAD-RUSH_Swiss Machines

- QUAD-RUSH_Parting & Shallow Grooving

- T-CLAMP_External Turn & Grooving

- T-CLAMP_External Profiling

- FACE-RUSH (TDFX)

- TSG-HF CBN Inserts_External Turning

- T-CLAMP_Face Grooving & Turning

- Modular System

- Chip Breakers for Parting and Grooving

- Chip Breakers for Groove-Turn

- Grade Selection Guide

- FACE MILL ARBOR

- TYPHOON (TJS)

- POS-S-TURN (XNMV)

- POS-S-TURN (ZNMV)

- TURN-SFEED (FCMX)

- HUSH-BORE (QH/QS)

- T-CLAMP_Internal Grooving & Turning

- WIN-GUN (TCDGN)

- WIN-GUN (TCDGN)

- C-ADAPTER

- WIN-SFEED

- WIN-TURN (TNMV)

- WIN-CUT (SFC/J)

- WIN-DRILL (TCD)

- WIN-MILL (AVK(C)T)

- POS-S-TURN (XNMV)

- POS-S-TURN (ZNMV)

- WIN-SWISS (QE1)

- MULTI-L-TURN (VBMX)

- HUSH-BORE (QH/QS)

- HUSH-MODU (QSS, C…CS)

- WIN-SWISS (QE1)

- QUAD-RUSH (TQBS)

- WIN-I-GROOVE (TMIR/L)

- FACE-RUSH (TDFX)

- VT-CLAMP (TDMV)

- WIN-DRILL (TCD-MRS,TCDM)

- DRILL-SFEED (3ED)

- SOLID-3-DRILL (3HD)

- SPADE-RUSH (LCD)

- XM-REAM (XR)

- WIN-MILL (CVKT)

- WIN-4-FEED (BLMV)

- CHASE-8-MILL (SQKU)

- CHASE-8-SFEED (SQKU)

- MAXI-TANG (4T...TR-)

- FINE-BARREL (NFLB, NFCB)

- SFEED-BARREL (BRHU)

- CERAMIC-SFEED (BNGX)

- T-CLAMP (TDCT)

Turning > Small Parts Machining

RHINO-TURN-SWISS

(Eco Type Negative Inserts)

Double-Sided Economical Inserts for Swiss Turning

» Double-sided ground precise inserts

» Excellent surface finish due to sharp cutting edges

» Excellent chip control and low cutting force

» Stable and strong screw clamp holders

» Suitable for Swiss turn machining

Double-Sided Economical Inserts for Swiss Turn Machining

For Swiss machining, RHINO-TURN’s double-sided inserts, which are characterized by their economical smaller size and stable machining prowess, have become the staple in the industry when it comes to machining various materials and cutting ranges with small depths of cut. The recently developed FU and FS chip breakers are now the archetype for Swiss turn machining. They offer excellent surface finish, longer tool life due to their sharp cutting edges, optimized chip breakers and unrivalled, highly effective grades.

TaeguTec’s various types of screw clamp holders guarantee stable machining without vibration in low cutting conditions as well as effortlessly process a variety of workpiece materials.

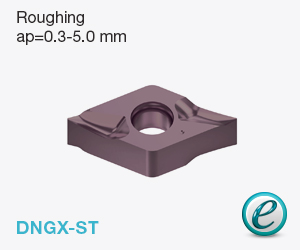

Compatible with RHINO turning holders, the 4-corner negative DNGX-ST insert with a high rake angle designed new chip breaker provides excellent machining performance and stable tool life due to the low cutting force generated during machining. The new chip breaker enables deep depth of cut machining up to 5.0 mm so that the number of required machining paths is reduced, resulting in higher productivity.

TaeguTec’s various types of screw clamp holders guarantee stable machining without vibration in low cutting conditions as well as effortlessly process a variety of workpiece materials.

Compatible with RHINO turning holders, the 4-corner negative DNGX-ST insert with a high rake angle designed new chip breaker provides excellent machining performance and stable tool life due to the low cutting force generated during machining. The new chip breaker enables deep depth of cut machining up to 5.0 mm so that the number of required machining paths is reduced, resulting in higher productivity.

Molded chip-breakers

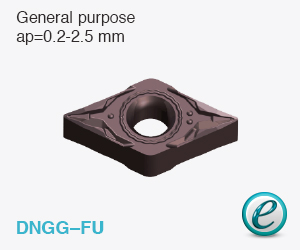

FU chip breaker

- Sharp cutting edges and clean surface finish

- Wide chip control range

- For Swiss type automatic lathes’ general purpose machining

- Low cutting load and vibration

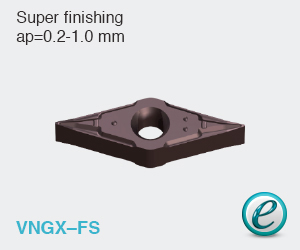

FS chip breaker

- Sharp cutting edges and clean surface finish

- Low cutting load and vibration

- For Swiss type lathes’ super finishing applications

- Low cutting load and vibration

ST chip breaker

- 5.0 mm maximum depth of cut

-Reduced number of machining paths for higher productivity - Continuous chip ensures low cutting force and a precise machining dimensions

- Recommended for use with the servo oscillation function in Swiss type machines

- Higher rake angle design for low cutting force