Linhas de Produtos

Ferramentas de Corte

category

- WIN-SWISS (QE1)

- WIN-I-GROOVE (TMIR/L)

- WIN-I-GROOVE (TMIR/L)

- WIN-4-FEED (BLMV)

- XM-REAM (XR)

- WIN-MILL (AVK(C)T)

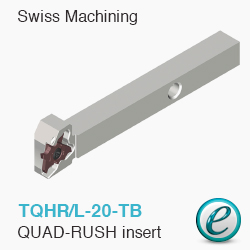

- QUAD-RUSH_Swiss Machines

- BT FC

- WIN-DRILL (TCD)

- WIN-DRILL (TCD-MRS,TCDM)

- CHASE-8-SFEED (SQKU)

- MAXI-TANG (LXHU)

- CHASE-8-SFEED (SQKU)

- CERAMIC-SFEED (BNGX)

- MODU-R-DRILL (MDB)

- SOLID-3-DRILL (3HD)

- CHASE-4-FEED (BLMP)

- CHASE-2-FEED (BLMP 13)

- CHASE-10-MILL (PTKU)

- NAN-RUSH (HFN)

- WIN-MILL (CVKT)

- TANG-SFEED (LPKU)

- CHASE-8-MILL (SQKU)

- CHASE-4-MILL (4NKT, 4NHT)

- CHASE-V-QUAD (SVKT)

- CHASE-12-MILL (HXKU, HXHU)

- CHASE-4-FINISH (4WHU)

- CHASE-10-MILL (PTKU)

- MAXI-SFEED (TR-)

- MAXI-RUSH (MX..)

- SLIK-SOLID (UHP 4)

- 5-Axis Profiling (SCS…,MXCS…)

- CERAMIC-SFEED (CR.)

- SFEED-BARREL (BRHU)

- FINE-BARREL (NFLB, NFCB)

- Carbide Endmills (SCS…,MXCS…)

- CHASE-SPEED for super alloys

- WIN-SWISS (QE1)

- MULTI-L-TURN (VBMX)

- Chip Breakers for Steel (..P)

- RHINO-TURN Series

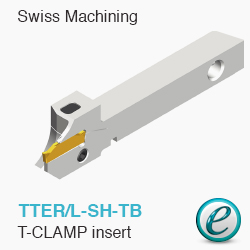

- T-CLAMP for Swiss Machines

- TOP-CUT for Swiss Machines

- MINI-I-RUSH for Swiss Machines

- J & C Type Chip Breaker

- TDV & TDUF Inserts

- TDXU & TDXY Inserts

- T Type Chip Breaker

- TDT-RU Chip Breaker

- TDIM & TDIP Inserts

- Aluminum Wheel Machining Inserts

- Tailor Made Inserts

- TOP-MINI Positive Inserts

- TOP-MINI Holders

- TT7505 Grade

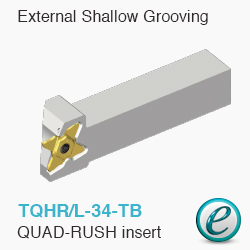

- QUAD-RUSH (TQC/J/S 27, TQC 34)

- QUAD-RUSH (TQJ/S 20)

- COOL-BURST High Pressure Coolant Holders

- TOP-MICRO for Swiss Machines

- T-THREAD (Thread Turning)

- TS-THREAD (Thread Milling)

- Modular System

- T-TAP (TPH-52B, TPH-54C)

- TOP-DRILL (TOP, SOMT)

- T-DRILL (TDR, SPMG)

- TOP-CAP (TCAP, XCMT)

- H-DRILL (NHD, NHD-K)

- M.Q.L-DRILL (SHO, Long Drill)

- T-DEEP (TRGD, Indexable Gun Drill)

- T-DEEP (BTA Drill)

- TM-REAMER (Head changeable)

- TB-REAMER (Blade type)

- T-GROOVE special solutions

- CHASE-FEED (SBMT)

- MILL-RUSH (3PKT)

- MILL-2-RUSH (6N*U, TNMX)

- CHASE-P-MILL (2PKT)

- CHASE-MILL (APKT)

- CHASE-ALU (XEVT)

- CHASE-HEPTA (7EMT)

- CHASE-2-HEPTA (XNMU, XNHU)

- CHASE-2-QUAD (SNMX, SNGX)

- CHASE-2-MOLD (RNMU)

- CHASE-MOLD (RYMX, RYHX)

- FINE-BALL (NFB/NFR)

- DUET-BALL (2FB)

- CHASE-2-BALL (6RBE)

- TRIO-BALL (3FB)

- TOP-SLOT (ZNHT, ZNHU, SLOT, TS16)

- Slotting Cutters (TIMC, TIMJ, TIPV)

- STAR-MILL (SED, SER, SBT, REH)

- HARD-MILL (HSF, HSR, HSB)

- Chamfering (HCEM)

- SOLID-FEED (HFM)

- VFI-MILL (CFM)

- MULTI-MILL (FSM)

- ALU-MILL (AES, AWE, REA, REMA)

- DIA-MILL (R*FE, RCOM, RDCF, D**)

- T-SHRINK

- T-BALANCE

- MPT

- QUAD-RUSH (TQBS)

- VT-CLAMP (TDMV)

- MILLING CHUCK (-NTMC)

- CUT-SFEED

- DRILL-SFEED (3ED)

- External Turning Tool Holders

- POS-S-TURN (XNMV)

- TURN-SFEED (FCMX)

- POS-S-TURN (ZNMV)

- RHINO-X-TURN (XNMG)

- RHINO-M-TURN (C/W/DNMX)

- HUSH-BORE (QH/QS)

- COOL-BURST (T…-TB)

- CUT-SFEED (SFC/J)

- QUAD-RUSH (TQS/J 20)

- QUAD-I-RUSH (TQIS)

- MINI-I-RUSH (TMIS)

- FACE-RUSH (TDFX)

- TSG-HF CBN Inserts

- SOLID-3-DRILL (3HD)

- DRILL-SFEED (3ED)

- DRILL-RUSH (TCD)

- MODU-R-DRILL (MDB)

- TANG-SFEED (LPKU)

- CHASE-4-MILL (4NKT)

- CHASE-8-MILL (SQKU)

- CHASE-4-FEED (BLMP)

- WIN-TURN (TNMV)

- MULTI-L-TURN (VBMX)

- HUSH-MODU (QSS, C…CS)

- WIN-TURN (TNMV)

- POS-S-TURN (XNMV)

- CHASE-2-MILL (ANHX, ANMX)

- TS-REAMER (Solid carbide)

- Inserts for Super Alloys

- SFEED-RUSH (CVD coated)

- Ceramic Inserts

- CBN and PCD Inserts

- DRILL-RUSH (TCD)

- SPADE-RUSH (LCD)

- BT FC

- SFEED-TEC Overview

- Holemaking by Products

- TURN-SFEED (FCMX)

- Milling by Applications

- POS-S-TURN (ZNMV)

- Thread Making by Products

- Tooling System by Products

- CDF-DRILL for CFRP (CDF)

- RHINO-X-TURN (XNMG)

- Turning Overview

- RHINO-M-TURN (C/W/DNMX)

- MINI-I-RUSH_Internal Shallow Grooving(TMIS)

- COOL-BURST (T…-TB)

- QUAD-I-RUSH_Internal Shallow Grooving(TQIS)

- WIN-CUT & CUT-SFEED (SFC/J)

- FACE-RUSH (TDFX)

- Parting & Grooving Overview

- Internal Turning Tool Holders

- HUSH-BORE (QH/QS)

- HUSH-MODU (C…CS)

- RHINO-M-TURN (C/W/DNMX)

- COOL-BURST High Pressure

- Heavy Duty Machining

- Chip Splitter Type Inserts (-SM, -SAL)

- CHASE-12-MILL (HXKU, HXHU)

- CHASE-10-MILL (PTKU)

- CHASE-4-FINISH (4WHU)

- CHASE-V-QUAD (SVKT)

- NAN-RUSH (HFN)

- MILL-RUSH (3PKT)

- MAXI-RUSH (MX..)

- MAXI-SFEED (TR-)

- CERAMIC-SFEED (BNGX)

- CERAMIC-SFEED (CR.)

- The others

-

RHINO-M-TURN

(Mini Size Negative Inserts) - TSK SLIM CHUCK (-TSK )

-

RHINO-TURN-SWISS

(Eco Type Negative Inserts) - Grade Selection Guide

- T-CLAMP_Parting & Deep Grooving

- QUAD-RUSH_Swiss Machines

- QUAD-RUSH_Parting & Shallow Grooving

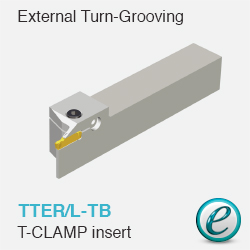

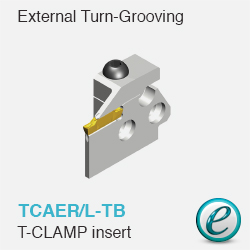

- T-CLAMP_External Turn & Grooving

- T-CLAMP_External Profiling

- FACE-RUSH (TDFX)

- TSG-HF CBN Inserts_External Turning

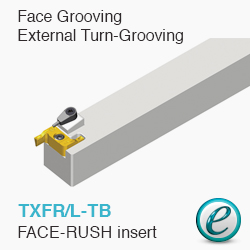

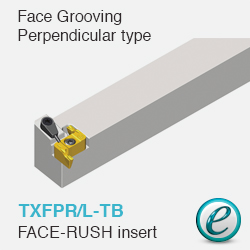

- T-CLAMP_Face Grooving & Turning

- Modular System

- Chip Breakers for Parting and Grooving

- Chip Breakers for Groove-Turn

- Grade Selection Guide

- FACE MILL ARBOR

- TYPHOON (TJS)

- POS-S-TURN (XNMV)

- POS-S-TURN (ZNMV)

- TURN-SFEED (FCMX)

- HUSH-BORE (QH/QS)

- T-CLAMP_Internal Grooving & Turning

- WIN-GUN (TCDGN)

- WIN-GUN (TCDGN)

- C-ADAPTER

- WIN-SFEED

- WIN-TURN (TNMV)

- WIN-CUT (SFC/J)

- WIN-DRILL (TCD)

- WIN-MILL (AVK(C)T)

- POS-S-TURN (XNMV)

- POS-S-TURN (ZNMV)

- WIN-SWISS (QE1)

- MULTI-L-TURN (VBMX)

- HUSH-BORE (QH/QS)

- HUSH-MODU (QSS, C…CS)

- WIN-SWISS (QE1)

- QUAD-RUSH (TQBS)

- WIN-I-GROOVE (TMIR/L)

- FACE-RUSH (TDFX)

- VT-CLAMP (TDMV)

- WIN-DRILL (TCD-MRS,TCDM)

- DRILL-SFEED (3ED)

- SOLID-3-DRILL (3HD)

- SPADE-RUSH (LCD)

- XM-REAM (XR)

- WIN-MILL (CVKT)

- WIN-4-FEED (BLMV)

- CHASE-8-MILL (SQKU)

- CHASE-8-SFEED (SQKU)

- MAXI-TANG (4T...TR-)

- FINE-BARREL (NFLB, NFCB)

- SFEED-BARREL (BRHU)

- CERAMIC-SFEED (BNGX)

- T-CLAMP (TDCT)

Parting & Grooving > High Pressure Coolant Holders

COOL-BURST High Pressure Coolant Holders

Pinpointed High-Pressure Coolant Directly to the Cutting Edge

» High productivity due to higher cutting speed and feed

» Longer tool life and excellent chip evacuation

» More efficient on difficult-to-cut materials such as super alloys

» Recommended coolant pressure 70 bar & Max 140 bar

Pinpointed High Pressure Internal Coolant Shooting Directly to the Cutting Edge

In order to meet the machining needs of difficult-to-cut materials such as titanium, Inconel and other heat resistant alloys, TaeguTec offers the exceptional COOL-BURST high-pressure coolant tool for turn-grooving and parting.

In parting and grooving applications, the ability to supply high-pressure coolant generates good chip breaking, reduced cycle times and increased tool life on most materials. On these difficult-to-cut materials, it is hard to ensure effective chip breaking specifically with standard external coolant in low feed rate operations. The COOL-BURST, by applying high-pressure coolant directly to the insert’s cutting edge, results in excellent chip breaking capability.

Moreover, the high-pressure coolant eliminates built-up-edges and maximizes insert tool life.

In parting and grooving applications, the ability to supply high-pressure coolant generates good chip breaking, reduced cycle times and increased tool life on most materials. On these difficult-to-cut materials, it is hard to ensure effective chip breaking specifically with standard external coolant in low feed rate operations. The COOL-BURST, by applying high-pressure coolant directly to the insert’s cutting edge, results in excellent chip breaking capability.

Moreover, the high-pressure coolant eliminates built-up-edges and maximizes insert tool life.

Full Line-up COOL-BURST High-Pressure Coolant Holders

- Upper coolant channel: result in better chip evacuation and tool life

- Lower coolant channel: result in better tool life

- Dramatically increased tool life under the same coolant pressure and cutting conditions as external coolant holders

- Dramatically increased productivity by supplying higher speeds and feeds with the same tool life compared to external coolant holders

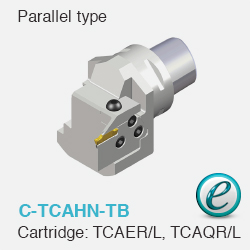

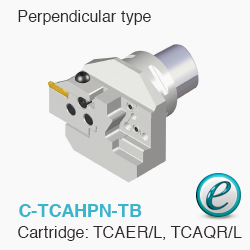

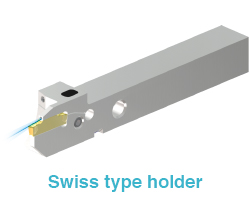

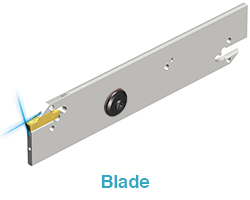

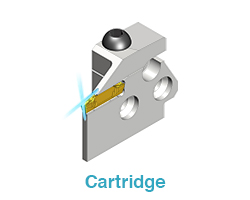

Holders, Cartridges and C-Adapter

* -TB: COOL-BURST high pressure coolant directly to the cutting edge