Information

New Products

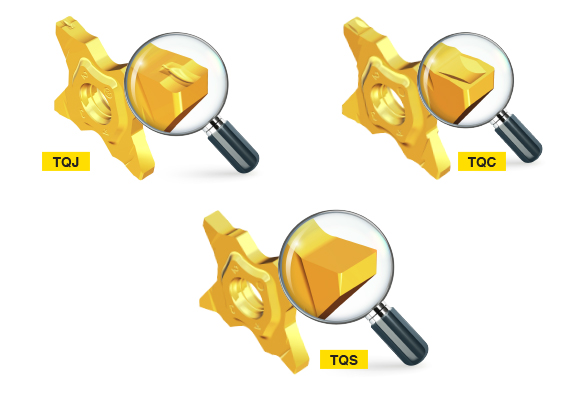

TaeguTec is introducing two new chip breakers and expanding its “J” chip breaker to include the handling of circlip grooving applications for its very popular QuadRush product line.

Due to its unique four cutting edges that allows for excellent performance and repeatability in grooving, parting and turning applications, QuadRush has taken the metal removing market by storm.

The expansion of the “TQJ” chip breaker for the QuadRush series gives TaeguTec a strong presence for grooving products that use circlips. The “TQJ” line offers good chip control, tolerance and surface finish and conforms to the DIN 471 standards of external circlips.

The two other chip breakers added to the QuadRush line, “TQC” and “TQS,” have been developed for grooving and parting operations on a wide range of cutting conditions.

The “TQC” type’s improved chip breaking properties is for industrial users that require increased productivity in high cutting conditions due to its high-feed rate and is designed to machine hard materials tough applications is perfect for general applications on steel, alloy steel and stainless steel, and is designed for good chip evacuation in medium to high-feed rate cutting conditions (0.05-0.25 mm/rev).

On a general carbon steel workpiece, QuadRush’s TQC chip breaker increased tool life by a whopping 433 percent against a leading competitor’s offering.

On the other hand, TaeguTec’s “TQS” chip breaker is made for industrial users in the metal removing field who are looking for tools that can outperform others when grooving and parting products made from soft materials.

QuadRush’s “TQS” insert type is available in widths up to 5.2 mm and can be applied to standard and special items, and is available for any special profile needed by customers.

As it is available in several width types and cutting shapes, it has the capacity to reduce the machining cycle time compared to existing tools and its straight cutting edges with high positive rake angle enables reduced cutting resistance.

Both the “TQS” and TQC” can produce the flat bottoms of workpieces and both are perfect solutions on a wide range of shallow grooving applications.

Visit www.taegutectimes.com for more information or contact your local TaeguTec representative.