Information

New Products

A new years is the time to say goodbye to the old and to usher in the new while at the same time, trying to live up to resolutions for a better life.

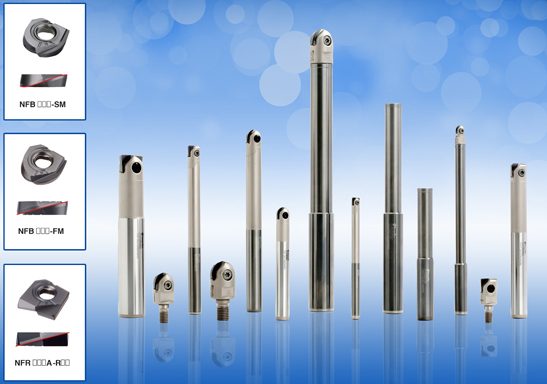

TaeguTec, one of the largest metalworking companies in Asia, is saying goodbye to two current coated grades in the FineBall line in order to improve upon the popular finishing tool used in the mold and die and aerospace industries.

The two new grades, the TT5515 and TT5525, will expand the line’s machining range to include various steel types like never before.

Their higher wear resistance and improved anti-chipping performance makes the FineBall an all around superior tool that increases productivity while cutting on cost.

Furthermore, the FineBall line is characterized by more rigid and secure clamping while its internal coolant system permits excellent chip evacuation and prolonged tool life.

The TT5515 is a high-wear resistance, high performance grade recommended for medium-speed to high-speed machining, covers all ISO ranges and is ideal for the machining of parts made from alloy steel, pre-hardened steel and hardened steel.

On the other hand, the TT5525 is optimally balanced with wear resistance and anti-chipping properties and is perfect for general machining of carbon steel and alloy steel.

The reason for the change is simple, in every test tool life was increased by as much as 60 percent over similar offerings from the competition.

For example, with all machining parameters being the same, the TT5515 blew away the competition by 60 percent while machining a workpiece made of SKD11 material. On a separate test on an SKD11 (HRC 62) workpiece, TaeguTec’s FineBall coated with the TT5515 also increased tool life against the competition by 50 percent.