Информация

Новости о продукции

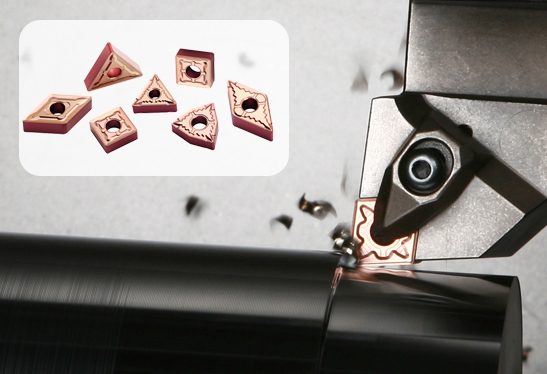

As the range of applications grows, so does the availability of tools with TaeguTec expanding its line of EA and ET chip breakers for its T-Turn line.

The expanded line offers excellent performance on stainless steel machining while handling a wider range of applications.

The EA chip breaker is designed to handle semi-finishing and finishing applications by controlling chips at a very low depth of cut and feed rate. Its sharp cutting edge has been adopted for smooth cutting which improves surface finishes and increases accuracy.

Furthermore, the EA chip breaker is designed with a very high positive geometry that minimizes built-up-edges and reduces machining loads. Its sharp cutting edge delivers excellent surface finishes.

For rough stainless steel machining applications, TaeguTec’s ET chip breaker’s positive rake angle reduces machining load and minimizes built-up-edges. In addition, the geometry helps to reduce heat generated while machining.

Due to its high positive chip former, the ET series of T-Turn inserts is perfect for high depth-of-cut and high feed rates.

Both the EA and ET chip breakers are an ideal choice for machining exotic and are both enhanced by TaeguTec’s critically-acclaimed GoldRush grades – the TT9125, TT9225 and the TT9235.

While the EA and ET chip breakers stand on two opposite sides of the machining spectrum, the EM chip breaker for the T-Turn is ideally placed right in the middle, able to machine stainless steel and exotic materials while reducing loads during medium machining applications.

Furthermore, the heat dissipation design on the upper side of the chip breaker minimizes heat generation on the cutting edge and, thus, maximizes tool life.