Информация

Новости о продукции

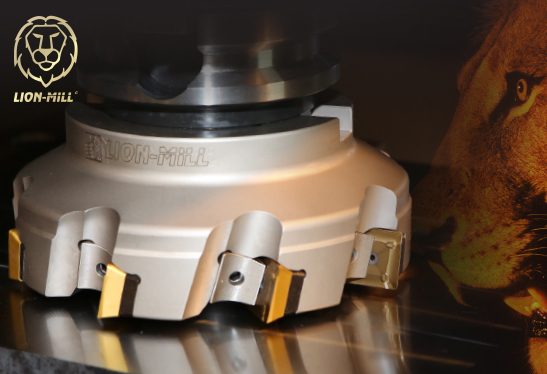

TaeguTec’s LionMill series has added a 90-degree line of cutters and inserts to its already hugely popular 60-degree family.

The newly developed 90-degree cutter’s unique dovetail wedge design securely fastens the insert with a powerful clamping force that ensures stable machining and improves precision, tool life and surface finishes.

To facilitate excellent chip evacuation, TaeguTec’s LionMill Heavy 90-degree cutters and inserts use a wide chip gullet.

Furthermore, a thick shim was introduced in this series in order to improve overall stability and durability.

The LionMill’s wedge clamping system simplifies assembly thus saving tool setting time and also saves precious machining minutes by permitting the operator to change the inserts without having to remove the tool from machine spindle itself.

LionMill Heavy 90-degree series’ high positive rake angle reduces cutting loads while the strong SEKX 21 millimeter insert with 7 mm thickness means optimal operation in heavy machining conditions with depths of cut up to 17 mm.

Its true 90-degree entering angle equipped with four cutting edges ensures longer tool life and overall value for the customer.

The inserts for the LionMill Heavy are available in TT7800 and TT6080 grades for the machining of a diverse range of low- and high-carbon steels, alloy steels and cast iron.

During two case studies, LionMill Heavy 90-degree cutters and inserts outperformed the competition by as much as 50 percent.

In the first study, TaeguTec tested its new line on a ship engine made from low carbon steel. While using the new LionMill Heavy 90-degree inserts, the SEKX 2107 PETR-M, TaeguTec was able to increase productivity from a competitor by 33 percent during an operation that involved a depth of cut of 6 mm, a width of cut of 260 mm and a cutting speed of 148 m/min.

On a trickier test, TaeguTec machined a lever used in the oil and gas sector made from alloy steel. At 150 m/min and a depth of cut of 6 mm, TaeguTec’s LionMill Heavy 90-degree tools were able to increase productivity by 50 percent.