Informações

Novidades de Produtos

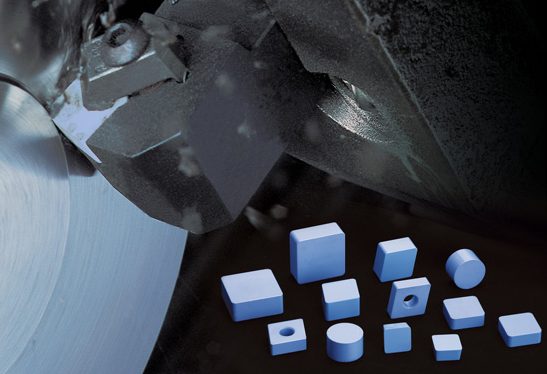

New Ceramic Grade for Dry, High Speed Cast Iron Turning

Dry machining is becoming a hot topic lately due to new regulations in the European Union and the United States about to take shape.

Yet, dry machining issues that plague machine shops such as the inability to cut dry at higher speeds and the changeover cost is making many manufacturers race for solutions.

In response, TaeguTec unveiled a brand new ceramic insert turning line that has excellent oxidation resistance, high chemical stability as well as temperature resistance that prolongs tool life under high cutting speed conditions.

The AW120 ceramic grade inserts’ economical characteristics and ability to increase productivity are highlighted by its design which aims at finishing, semi-finishing and roughing applications on cast iron under high cutting speed conditions.

More specifically, the AW120 was adapted as an optimal tool for the machining of cylinder liners where high cutting speeds under dry conditions are the norm.

Once balanced with TaeguTec’s cost reduction technology and advanced metal cutting strategies, manufacturers will combine the accurate productivity of high-speed machining with the benefits of dry machining.

In these changing times where government policy dictates machining conditions, it has become more important than ever for companies to integrate the right tool with proper engineering know-how in this case, the AW120 and TaeguTec’s qualified service technicians and sales force.