Información

Noticias Productos

June 10 – To meet market demand in several key sectors, TaeguTec is expanding its MillRush next generation 90 degree, 3-helical cutting edge insert line by offering three new types.

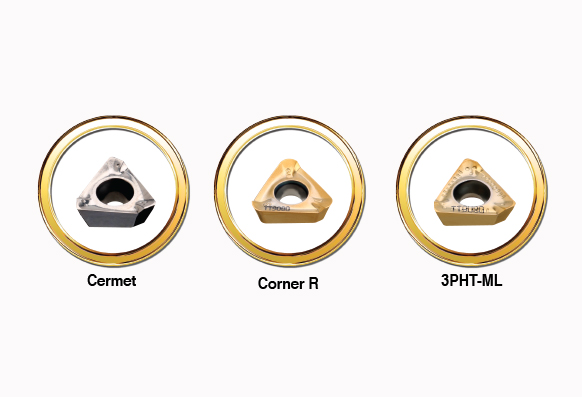

By expanding the line to offer a cermet grade, a peripherally ground with ML chipformer and expanded corner radii types, TaeguTec answers the call from companies searching for tools that can handle a wider range of applications in the ever evolving general machining, mold and die, aerospace and power generation industries.

Out of the MillRush line expansion, the new cermet grade’s handling of wide milling applications and longer tool life is ideal for high speed machining on alloy steel, carbon steel, stainless steel and cast iron, and is the optimal solution for finishing general and mold and die components.

Designed for machining high temperature super alloys widely used in the aerospace and power generation industries, the peripherally ground ML chipformer – also known as the 3PHT-ML – achieves excellent surface finish, promotes smooth cutting, consumes less power and reduces run out all features that make this tool perfect for higher precision machining.

The peripherally ground ML chipformer, or 3PHT-ML, blew away the competition’s similar offering during two separate product tests by increasing tool life by 122 percent and 100 percent while using the same cutting conditions such as speed, feed rate and depth of cut.

The third newest offer from TaeguTec’s MillRush series is the expanded corner “R” radius insert which covers a wide array of applications while handling a full range of radii options up to 3.2 millimeters.