Products

Cutting Tools

Turning > Chip Breakers and Grades

Chip Breakers for Steel (..P)

FLP, MLP, MGP and RGP chip breakers for steel machining

» FLP chip breaker for finishing

» MLP chip breaker for semi-finish to medium

» MGP chip breaker for medium

» RGP chip breaker for roughing

» Improved stability and tool life

» Excellent chip control performance

» Wide application range to cover the current line of chip breakers

Wide Range of Chip Breakers for Steel

Focusing on the market’s requirement in automation and improved productivity, TaeguTec’s series of optimized chip breakers and grades offer improved stability, longer tool life, excellent chip control performance while covering a wide range of applications.

Overall, these chip breakers deliver optimal machining performance and high reliability in a wider range of operations.

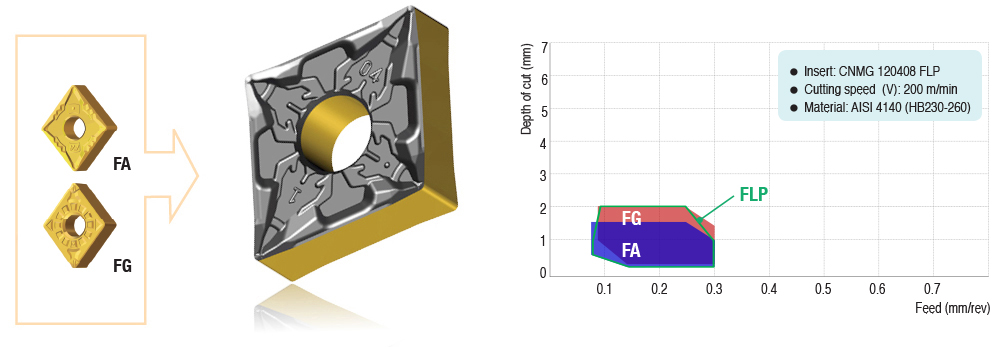

FLP type

The FLP chip breaker (for finishing) minimizes machining load at low depths of cut, has excellent chip control capability due to the wide, stable supporting area, and enables excellent workpiece dimensional accuracy.

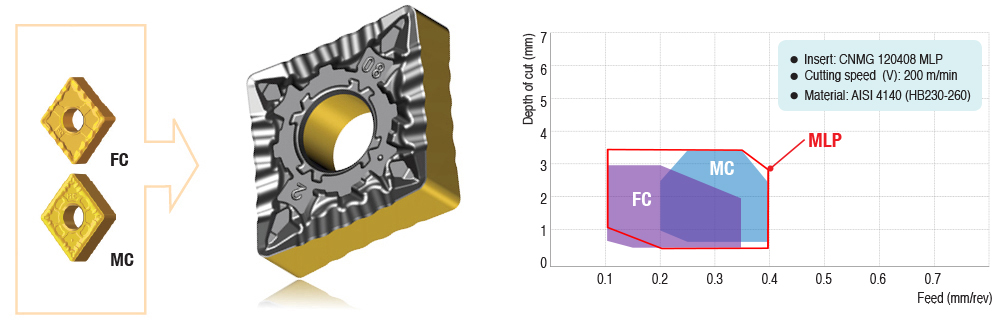

MLP type

The MLP chip breaker (for semi-finishing to medium) enables excellent chip control capability due to the side wave edge geometry in highly variable depths of cut, and with a specially designed edge that enables stable machining in a wide range of medium applications.

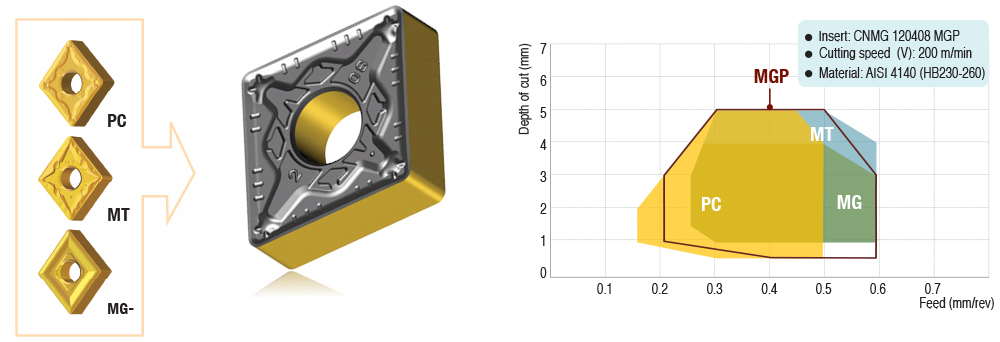

MGP type

The MGP chip breaker (for medium), characterized by good chip control, is the first recommended machining solution for a wide range of operations. Also, the MGP is designed with cutting edge strength and has a wide support area that promotes stable and reliable machining.

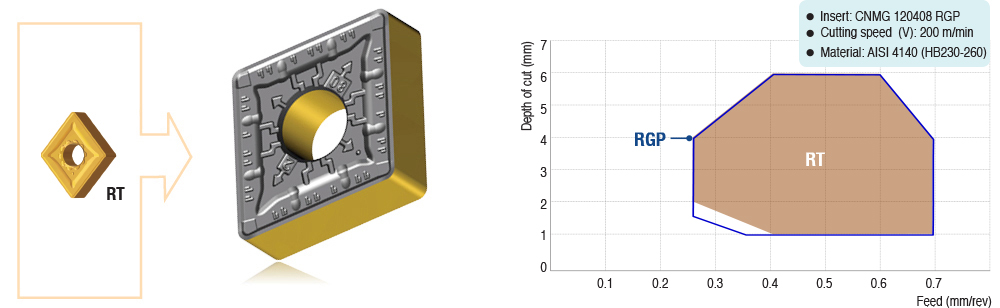

RGP type

The RGP chip breaker (for roughing) is suitable for roughing applications due to its reinforced cutting edge and wide chip groove, and can perform reliably without chipping even in extreme interrupted machining conditions.