Products

Cutting Tools

category

Turning > Small Parts Machining

TOP-MINI Positive Inserts

Chip Breakers and Grades for Swiss Turn Machining

» G tolerance insert with accurate minus tolerance in corner radius

» SL, SM and SH chip breakers for suitable applications

» BTVC back turning insert

» TT4410 and TT4430 PVD coated grades for steel, stainless steel and super alloys

» Excellent surface finish and longer tool-life after machining

New Miniature TOP-MINI Grades, Chip Breakers Heighten Swiss Lathes

TaeguTec has developed new enriched PVD coated grades and sophisticated new chip breakers to effectively handle various materials and cutting ranges for Swiss automatic lathes. The innovative new features for the TOP-MINI offer excellent surface finish and longer tool life. The G-tolerance insert with accurate minus tolerance in corner radius as well as the SL, SM, SH and ST chip breakers are accentuated with the newly developed PVD coated grades that not only improve performance but enhance machining capabilities. The result is excellent surface roughness and finish, and extraordinary chip control under low machining conditions, as well as the ability to process a variety of workpiece materials without the need of grade replacement.

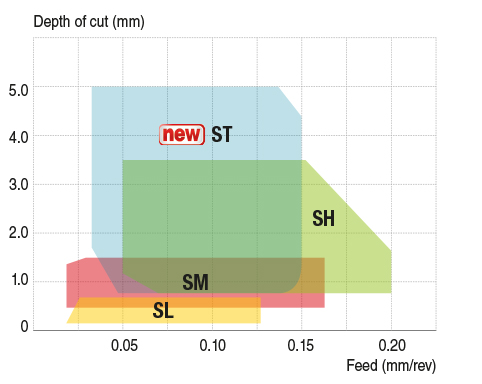

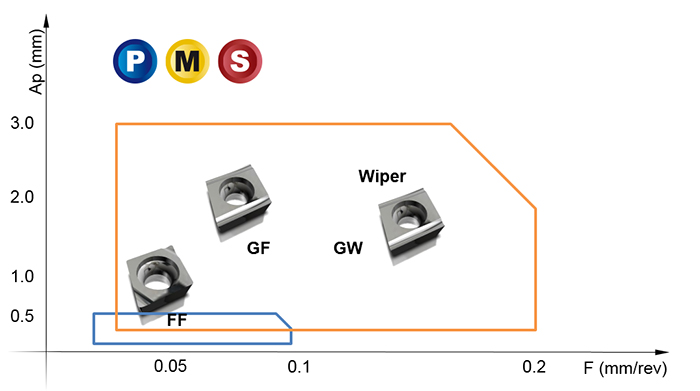

Molded chip-breakers

SL chip breaker

- High performance in low depth of cut and low feed machining

- Excellent chip segmentation due to wave geometry edge and special inclined design

- Recommended depth of cut: 0.02-0.25 mm

SM chip breaker

- 1st recommended chip breaker for Swiss type automatic lathes

- Stable cutting edge and low cutting resistance

- Long tool life and good surface roughness

- Recommended depth of cut: 0.2-1.5 mm

SH chip breaker

- Suitable for deep depth of cut machining

- Excellent chip control in a wide machining range

- A well coordinated cutting edge with sharpness and stiffness for various machining

- Recommended depth of cut: 0.7-3.5 mm

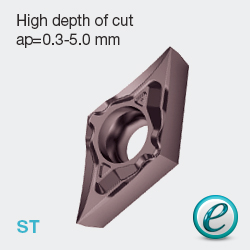

ST chip breaker

- 2-corner positive insert for small part machining

- 5.0 mm maximum depth of cut - Reduced number of machining paths for higher productivity

- Higher rake angle design for low cutting force

- Recommended depth of cut: 0.3-5.0 mm

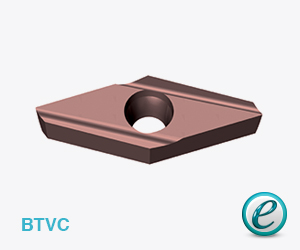

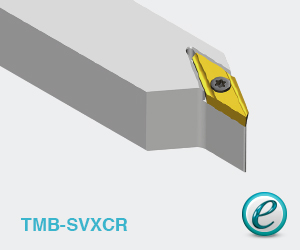

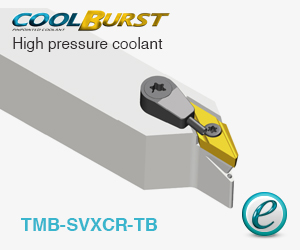

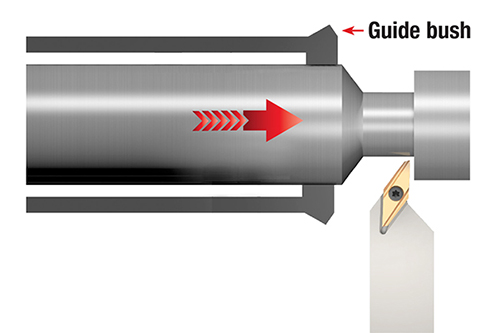

Back turning inserts and holders

- Excellent chip control with sharp edge

- Good surface finish with wiper design

Holder is away from guide bush, so finishing cut is performed without retracting workpiece from guide bush

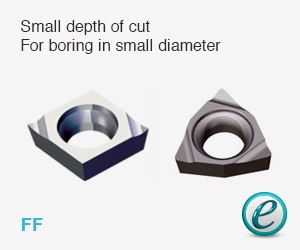

Ground chip breakers (Handed type)

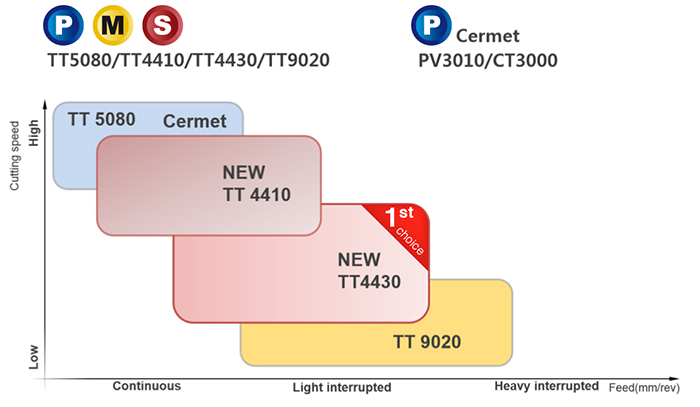

PVD coated grades for swiss turn machining

TT4410 grade

- High wear resistant micro-alloy substrate with excellent ground quality

- Multi AlTiCrN coating layer with improved bonding on substrate and anti-adhesion of workpiece material

- Suitable for steel, stainless steel, heat-resistant super alloy and Ti-alloy in high-speed continuous cutting

- Suitable for hardened steel in low-speed continuous cutting

- Dark brown color

TT4430 grade

- High toughened micro-alloy

- Multi AlTiCrN coating layer with stabilized edge, anti-adhesion of workpiece material and high chipping resistance

- Suitable for steel, stainless steel, heat-resistant super alloy and Ti-alloy in low-medium speed continuous cutting and light interrupted cutting

- Dark brown color