Products

Cutting Tools

category

Milling > Profiling

FINE-BALL (NFB/NFR)

High-Precision and Excellent Run-out Insert for Finishing Applications

» High-precision and excellent run-out blade type inserts

» Asymmetric pocket design enables high-precision and better clamping

» Internal coolant channels offer good chip evacuation and better tool life

» Various steel and tungsten carbide shanks for deep cavity machining

» Profiling and various applications

High-Precision and Excellent Run-out Indexable Inserts for Finishing Applications

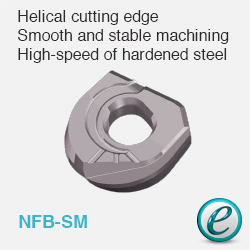

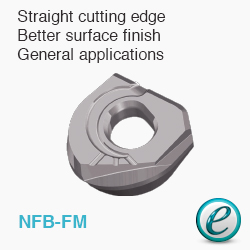

FINE-BALL, TaeguTec’s highly effective solution for finishing end mills in the machining of mold and die and aerospace components delivers smooth and stable performance with excellent runout and precision. The unique features of the line’s inserts and holders are available as either Ball type, with a diameter from 6-32 mm, or Corner R types that includes a corner radius of 0.3-3.0 mm. Moreover, for effective finishing, both have a range of 6-32 mm. The TNF holder can accommodate both the Ball and Corner R type inserts while the TNFR cutter is designed specifically for R type inserts only. End mill bodies are offered in steel, carbide or modular types. The FINE-BALL line is characterized by more rigid and secure clamping while its internal coolant system permits excellent chip evacuation and prolonged tool life.