Information

New Products

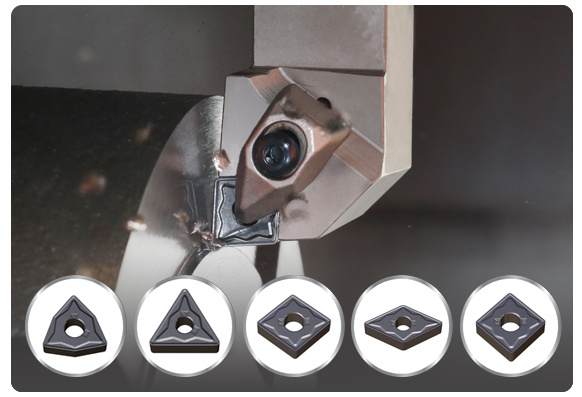

April 30, 2013 – TaeguTec has introduced a new chipbreaker to its line of inserts which is designed to handle rough turning of cast iron.

Moving away from the flat chipbreakers, TaeguTec’s KT chipbreaker offers a reliable and uniform performance when machining rough applications on cast iron.

By its nature, cast iron can be very awkward to deal with because of abrasive flank wear and thermal cracks on inserts.

Furthermore, other challenges the KT chipbreaker resolves on the component side is the frittering at the cutter exit of the workpiece and surface finish problems.

Tests have shown that the KT chipbreaker has increased tool life from 33 to 150 percent compared to other inserts.

The KT chipbreaker’s broad supporting area for stable seating as well as reinforced cutting edges due to its strong T-land offers manufacturers reliable and uniform machining.

Furthermore, its excellent tool life for roughing and interrupted cutting conditions makes the introduction of the KT chipbreaker the perfect performer at a time when machining cast iron has become more important than ever.

The most impressive of the case studies conducted by TaeguTec was on clutch plates using ductile cast iron (FCD30, GGG30 and GCD300). The facing and interrupted operation using no coolant outstripped the competition by increasing tool life by 150 percent when operating the machine at a cutting speed of 527 m/min, a feedrate of 0.12 to 0.18 mm/rev and a depth of cut of 2.5 mm.

Another test performed on a carrier workpiece made from ductile cast iron (FCD45, GGG45 and GCD450) found that during internal facing and interrupted operations using lubricant, the new KT chipbreaker outperformed the competitor by 33 percent when machining the carrier at a speed of 210 m/min, a feedrate of 0.21 to 0.28 mm/rev and a depth of cut of 2.0 mm.